- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

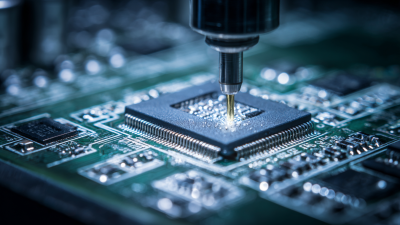

Understanding the Role of Pcb Board in Modern Electronics and Its Future Trends

The Printed Circuit Board (Pcb Board) is a fundamental component in the realm of modern electronics, serving as the backbone of nearly every electronic device today. According to industry reports, the global Pcb market is projected to reach approximately $80 billion by 2026, growing at a CAGR of around 4.5% from 2021 to 2026. This growth is fueled by the increasing demand for consumer electronics, automotive applications, and the rise of IoT devices.

As technology continues to advance, the Pcb Board is evolving as well, incorporating cutting-edge materials and design techniques to meet the rigorous demands for miniaturization, efficiency, and performance. The integration of advanced manufacturing processes, such as additive manufacturing and smart Pcb technology, is poised to revolutionize the industry, making it crucial for stakeholders to understand the current trends and future directions of Pcb Board development.

The Evolution of PCB Technology in Modern Electronics

The evolution of PCB technology has been significantly influenced by the rapid advancement of electronics and the emerging challenges associated with the AI era. As engineers face increasingly complex design requirements, the integration of artificial intelligence into PCB design processes has become essential. This shift not only enhances design efficiency but also enables the simulation of multiple physical fields, paving the way for more innovative and advanced electronic products.

Recent trends indicate a growing demand for high-density interconnect (HDI) PCBs, particularly in server applications. These PCBs leverage micro blind/buried via technology to optimize electrical connections across layers, resulting in improved performance and space efficiency. As industries continue to recover and adapt to new technological demands, the PCB sector is witnessing a resurgence, underscored by a notable increase in orders driven by the advancements brought on by AI. The future of PCB technology is set to revolutionize electronic design, ensuring that it keeps pace with the evolving landscape of modern electronics.

Key Components and Materials Used in PCB Manufacturing

In modern electronics, printed circuit boards (PCBs) are vital, serving as the backbone for circuits in countless devices. A typical PCB consists of a variety of key components and materials, each playing a crucial role in its functionality. Common materials include fiberglass, epoxy, and copper, which are utilized to form the substrate and conductive pathways. The choice of materials directly impacts performance factors such as thermal conductivity, electrical insulation, and mechanical strength.

Tips: When selecting materials for PCB manufacturing, consider the specific requirements of your application, such as the operating environment and electrical performance. This will help ensure durability and efficiency in your final product.

Additionally, components like resistors, capacitors, and integrated circuits are mounted on the PCB to create functional electronic systems. Advanced manufacturing techniques, including surface mount technology (SMT) and through-hole technology, have evolved to accommodate the miniaturization of devices, allowing for more complex designs within limited space.

Tips: Stay updated on the latest trends in PCB technology, such as the use of flexible PCBs and higher-density interconnects, as these innovations can significantly enhance device capability and performance.

Innovative Designs: Flexibility and Miniaturization of PCBs

In the realm of modern electronics, the demand for innovative designs has prompted significant advancements in printed circuit board (PCB) technology. Flexibility and miniaturization have emerged as pivotal trends in PCB design, enabling manufacturers to create compact devices without sacrificing functionality. Flexible PCBs, with their ability to bend and twist, allow for the integration of electronics in unconventional spaces, accommodating the growing trend of portable and wearable technology.

Miniaturization is closely tied to the advancements in materials and manufacturing techniques. As electronic components continue to shrink, PCBs have also evolved to support smaller, denser configurations. This not only improves performance but also facilitates the development of smart devices that require intricate circuitry in minimal space. The synergistic relationship between flexibility and miniaturization positions PCBs at the forefront of modern electronic innovation, allowing engineers to push the boundaries of design and create more efficient, versatile products for various industries.

Sustainability in PCB Production: Challenges and Solutions

The production of printed circuit boards (PCBs) has faced numerous sustainability challenges, as the electronics industry continues to expand. According to a report by the International Electronics Manufacturing Initiative (iNEMI), the global PCB market is projected to reach $80 billion by 2027, emphasizing the urgent need for sustainable practices in an industry under increasing environmental scrutiny. The conventional processes involved in PCB manufacturing contribute significantly to electronic waste, with wild estimates suggesting around 50 million tons of e-waste produced annually.

Emerging technologies and practices are being explored to address these sustainability challenges. For instance, innovative materials such as biodegradable substrates and lead-free soldering are becoming more prevalent. A study by the European Commission highlighted that adopting eco-design strategies could decrease the environmental impact of electronic products by up to 30%. Additionally, recycling efforts, including the recovery of valuable metals from spent PCBs, are gaining traction, fostering a circular economy within the electronics sector. By integrating these solutions, manufacturers can significantly reduce their carbon footprint while ensuring that the growth of the PCB market aligns with ecological sustainability goals.

Future Trends: The Role of AI and IoT in PCB Development

The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is poised to revolutionize the development of Printed Circuit Boards (PCBs) in the coming years. As industries increasingly adopt AI-powered design automation, PCB design processes are becoming more efficient and precise. This is largely driven by the demand for compact and efficient electronic components, crucial for modern devices such as smartphones and various IoT applications. In 2025, the PCB design software market is expected to expand significantly, fueled by hardware innovations that require advanced, smart designs.

Moreover, the trends in smart cities will further impact PCB development. These urban environments are becoming more reliant on IoT technology to improve sustainability, mobility, and quality of life. As smart cities evolve, PCBs will need to adapt to support a diverse range of devices and applications, from smart meters to autonomous vehicles. The future of PCB technology is not only about innovation in design but also about creating flexible and sustainable manufacturing processes that align with the growing emphasis on environmental responsibility.

Related Posts

-

Understanding Global Industry Standards for Best PCB Printed Circuit Boards in Modern Manufacturing

-

Top 10 Circuit Board Fabrication Manufacturers from China at the 137th Canton Fair

-

Global Leaders in PCB Assembly: Unlocking Top Quality and Efficiency for Worldwide Exports

-

Solutions for Exceptional Circuit Board Fabrication Techniques

-

Top Strategies for Sourcing Quality Electronic Circuit Boards Globally

-

Envisioning Tomorrow: The Evolution and Potential of PCB Board Technology

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved