- PCB Assembly

- PCB Fab

- Resources

- Company

- Blog

Unlocking Innovation: The Impact of Quick Turn PCB Boards on Modern Electronics

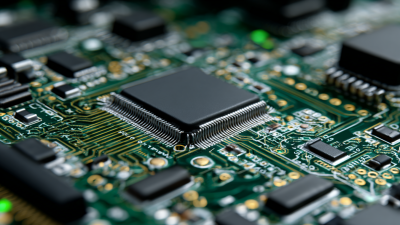

In today's fast-paced technological landscape, the demand for rapid innovation in electronics has never been greater. Key to this evolution is the emergence of Quick Turn PCB Boards, which have revolutionized the way designers and manufacturers approach product development. These specialized circuit boards offer a streamlined process that significantly reduces turnaround times, allowing for faster prototyping and iteration. As industries increasingly seek to respond to market needs with agility, Quick Turn PCB Boards provide a vital competitive edge, enabling companies to bring their ideas to life more swiftly and efficiently.

This article explores the transformative impact of these boards on modern electronics, highlighting practical tips for leveraging their capabilities to unlock innovation and enhance product offerings.

In today's fast-paced technological landscape, the demand for rapid innovation in electronics has never been greater. Key to this evolution is the emergence of Quick Turn PCB Boards, which have revolutionized the way designers and manufacturers approach product development. These specialized circuit boards offer a streamlined process that significantly reduces turnaround times, allowing for faster prototyping and iteration. As industries increasingly seek to respond to market needs with agility, Quick Turn PCB Boards provide a vital competitive edge, enabling companies to bring their ideas to life more swiftly and efficiently.

This article explores the transformative impact of these boards on modern electronics, highlighting practical tips for leveraging their capabilities to unlock innovation and enhance product offerings.

Understanding Quick Turn PCB Boards and Their Applications

Quick turn PCB boards, often referred to as rapid prototyping printed circuit boards, have revolutionized the electronics industry by significantly reducing the time-to-market for new products. According to a report by IPC, the global PCB market is projected to reach $79 billion by 2025, with quick turn services playing a crucial role in this growth. These services allow engineers to test and validate their designs rapidly, resulting in faster iterations and reduced development costs, which is essential in today’s competitive environment.

One of the key applications of quick turn PCB boards is in the development of consumer electronics. A study by ResearchAndMarkets highlights that the demand for quick turn prototypes in sectors like IoT, automotive, and medical devices is projected to grow at a CAGR of over 15% from 2021 to 2026. This trend is attributed to the increasing complexity of electronic designs and the need for precise and reliable prototypes. By enabling faster testing and modification processes, quick turn PCB boards not only support innovation but also enhance the overall efficiency of product development cycles.

Unlocking Innovation: The Impact of Quick Turn PCB Boards on Modern Electronics

| Application Area | Typical Lead Time | Common Materials | Cost Efficiency | Industry Usage |

|---|---|---|---|---|

| Consumer Electronics | 1-2 weeks | FR-4, Aluminum | High | Electronics Manufacturing |

| Medical Devices | 2-4 weeks | CEM-1, PTFE | Moderate | Healthcare |

| Telecommunications | 1-3 weeks | Rogers, Polyimide | High | Networking |

| Aerospace | 3-5 weeks | Flex Circuit, Kevlar | Moderate | Aerospace Engineering |

| Industrial Automation | 1-2 weeks | FR-4, Copper | High | Manufacturing |

The Design Process Behind Quick Turn PCB Prototyping

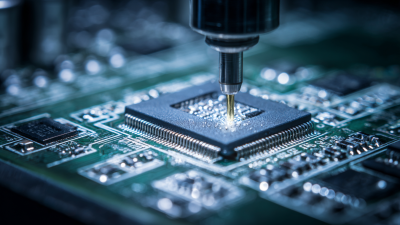

The design process behind quick turn PCB prototyping plays a crucial role in the rapid development of modern electronics. Unlike traditional PCB manufacturing, which can take weeks or even months, quick turn prototyping allows engineers to create and test circuit boards in a matter of days. This expedited timeline is facilitated by advanced design software and streamlined manufacturing techniques that prioritize efficiency without compromising on quality. The iterative nature of quick turn prototyping enables designers to make swift modifications in response to testing feedback, thus fostering innovation and creativity.

Moreover, the integration of rapid prototyping techniques reflects a shift in collaboration within engineering teams. Design engineers can work in tandem with manufacturers to optimize layouts and select materials more effectively. This close collaboration not only minimizes the risks of errors but also accelerates the overall development cycle. As a result, companies can quickly bring new products to market, respond to consumer trends, and stay competitive in an ever-evolving technological landscape. This synergy between design and manufacturing is essential for unlocking the full potential of innovative electronic solutions.

Exploring the Benefits of Rapid Prototyping in Electronics Development

Rapid prototyping has revolutionized the electronics development landscape, allowing engineers and designers to transform their ideas into tangible products swiftly. This process significantly reduces the time required to create printed circuit boards (PCBs), thereby enabling faster testing and iteration cycles. In an industry where market demands shift rapidly, being able to quickly redesign and produce PCB prototypes means that companies can stay competitive by adapting to the latest technologies and consumer preferences.

Additionally, rapid prototyping leads to enhanced collaboration among teams. With quick turn PCB boards, engineers can receive immediate feedback on their designs, facilitating better communication between design, development, and manufacturing teams. This iterative approach not only improves the quality of the final product but also fosters an innovative culture where creative solutions can be explored without the fear of lengthy lead times or excessive costs. By embracing rapid prototyping, companies are not just speeding up their processes; they are effectively unlocking new avenues for innovation in modern electronics.

Key Considerations for Choosing a Quick Turn PCB Manufacturer

When selecting a quick turn PCB manufacturer, it's essential to consider several key factors that can significantly impact the quality and efficiency of your project. First and foremost, assess the manufacturer's production capabilities. Ensure they possess advanced technology and machinery capable of producing high-density interconnect (HDI) boards, which are crucial for modern electronic applications requiring miniaturization without compromising performance.

Another vital consideration is the manufacturer's experience and reputation in the industry. Look for companies that have a proven track record in delivering reliable and timely services. Customer reviews and case studies can provide insight into their reliability and customer support. Additionally, evaluating their supply chain management is important, as this will influence lead times and the ability to meet tight deadlines, which is a cornerstone of quick turn services. By focusing on these aspects, you can make an informed choice that aligns with your unique project requirements.

Unlocking Innovation: The Impact of Quick Turn PCB Boards on Modern Electronics

This chart illustrates the average lead time and production speed of quick turn PCB manufacturers in relation to the complexity of the designs. Shorter lead times and reduced production durations enable faster innovation cycles in modern electronics.

Future Trends in Quick Turn PCB Technologies and Innovation

The rapid advancement of quick turn PCB technologies is reshaping the landscape of modern electronics. As industries demand faster product cycles, engineers are increasingly turning to quick turn circuit boards to expedite development processes. These technologies allow for accelerated prototyping, enabling designers to iterate their products efficiently while minimizing time to market. The ability to make swift adjustments during the development phase not only enhances creativity but also reduces costs associated with traditional manufacturing delays.

The rapid advancement of quick turn PCB technologies is reshaping the landscape of modern electronics. As industries demand faster product cycles, engineers are increasingly turning to quick turn circuit boards to expedite development processes. These technologies allow for accelerated prototyping, enabling designers to iterate their products efficiently while minimizing time to market. The ability to make swift adjustments during the development phase not only enhances creativity but also reduces costs associated with traditional manufacturing delays.

Looking ahead, several trends are poised to further revolutionize quick turn PCB technologies. The integration of automation and AI in the design and manufacturing processes is expected to streamline operations, making it easier for teams to achieve complex designs within tight timelines. Additionally, advancements in materials science will likely yield innovative substrates that enhance performance while maintaining agility in production. As these trends unfold, businesses will need to stay on the cutting edge of technology to harness the full potential of quick turn PCBs, ultimately driving a new wave of innovation in the electronics industry.

Related Posts

-

What is the Importance of Quality Control in Circuit Board Manufacturing

-

Top 10 Circuit Board Fabrication Manufacturers from China at the 137th Canton Fair

-

Global Leaders in PCB Assembly: Unlocking Top Quality and Efficiency for Worldwide Exports

-

Understanding Global Industry Standards for Best PCB Printed Circuit Boards in Modern Manufacturing

-

Solutions for Exceptional Circuit Board Fabrication Techniques

-

Envisioning Tomorrow: The Evolution and Potential of PCB Board Technology

Phone

WhatsApp

WhatsAppEmail

Offer Electronics Manufacturing All-in-One

PCBONLINE® is a registered trademark or service mark of pcb online limited or its affiliates.

Copyright © 2001-2024 Pcb Online Limited. All rights reserved